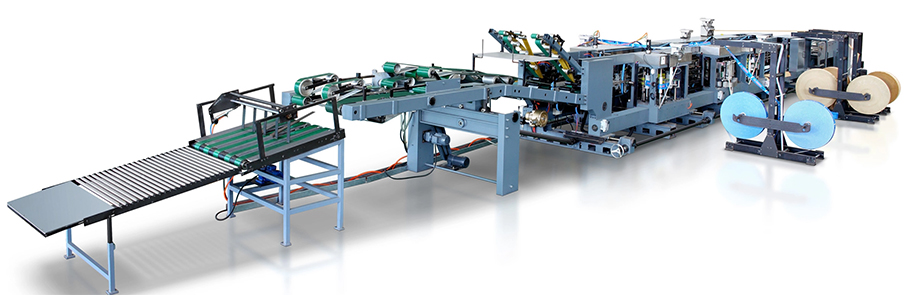

Umshini Ophansi we-LQ HD8916

Isithombe somshini

Ingakwazi ukuphatha izendlalelo zephepha ezingu-2-4:

● Ikwazi ukukhiqiza uhlangothi olulodwa oluvaliwe, isikhwama sephepha esisodwa esivulekile.

● Ngokuqiniswa kwangaphakathi kanye nendlela yokuqinisa yangaphandle (ongakukhetha).

● Iyakwazi ukukhiqiza isikhwama sephepha se-valve yesingqimba esisodwa, isikhwama sephepha se-valve yangaphandle esiyicylindrical, isikhwama esikhulu esingezansi nesikhwama sephepha se-valve encane, yangaphandle.isikhwama se-valve esinegebe lesithupha, nesikhwama se-valve ye-sonic.

| Uhlobo Lomshini | I-LQ HD8916 |

| Ubude besikhwama(mm) | 370-770 |

| Ububanzi besikhwama(mm) | 350-550 |

| Ububanzi besikhwama esingezansi(mm) | 90-160 |

| Ibanga eliphakathi kwesikhwama(mm) | 280-620 |

| Isivinini esikhulu sokuklama | 150strip/min 150tubes/min |

● Indlela yokudla

I-Rotary roller feeding method.I-rota encane izungeza i-roller enkulu, futhi ngesikhathi esifanayo ijikeleze ngokuhlehla ukuze imunce ishubhu lephepha. Irola elikhulu lingakwazi ukumunca amashubhu ephepha angu-8 ukuze lizungezise umzuliswano owodwa.

Umshini wokuphakela iplanethi yokuzungeza i-vacuum inendlela elula, futhi ithembekile futhi izinzile.

● Ukuhlunga kanye nendlela yokubhoboza

Ifakwe idivayisi yokubeka ukuze kuqinisekiswe ukunemba kokuma kwamashubhu ephepha lapho kungena inqubo elandelayo.

Ifakwe idivayisi ye-oblique indentation, indawo ye-oblique indentation ingalungiswa ngaphandle kokumisa umshini.

Ifakwe umsebenzi wokubhoboza imbobo yokukhipha, ikakhulukazi esetshenziselwa ukukhiqizwa kwezikhwama zephepha zikasimende.Ingakwazi ukubhoboza isikhwama sonke, futhi umkhono wenaliti ogwaziwe ungasuswa ngokushesha.

Ifakwe umsebenzi wommese wokusika oqondile, usike izindwani ezimbili ezingxenyeni ezimbili zesikhwama sephepha, ezisetshenziswa kakhulu kwinqubo yokunamathisela-phansi yokwenza amashubhu ephepha ayisicaba.

● Vula indlela yokwenza isicaba

Ifakwe i-vacuum suction mechanism, esetshenziselwa ukuvula umlomo wamashubhu ephepha, ukuze uphondo lomshini lufakwe kahle emlonyeni wamashubhu ephepha.

Ifakwe umshini wophondo, wokuvula umlomo wezikhwama zephepha bese uwenza ube umumo wedayimane olinganayo.

Ifakwe umshini wokucaba ukuze usize uphondo lwakhe olungaphansi kwesikhwama sephepha, futhi ihlanganise isakhiwo esimise okwedayimane ngaphansi kwesikhwama sephepha.

● Imbobo yembobo ye-Flake*

Umshini usike itheyiphu yephepha levalvu ukwenza iphepha levalvu, bese unamathisela iphepha levalvu ezikhwameni.

Ingenza i-valve yangaphandle noma eyakhelwe ngaphakathi ngongqimba olulodwa lwephepha, kanye nefilimu yephepha engaqondani kahle ne-valve eyakhelwe ngaphakathi.

Inomshini wokuhlukanisa, ongalungisa ukuma kwephepha le-valve elifakiwe ngaphandle kokumisa umshini.

Shintsha amapharamitha esibukweni ukuze usethe ubude bephepha lembobo yesivalo.

● Indlela yembobo yevalvu eyi-cylindrical*

Umshini usike itheyiphu yephepha levalvu ukwenza iphepha levalvu, bese ugoqa bese unamathisela iphepha ukwenza ishubhu. Bese ekugcineni unamathisele iphepha le-valve ezikhwameni;

Ifakwe idivayisi yokulungisa umehluko, itheyiphu yephepha ingashintshwa kalula ngaphandle kokumisa umshini;

Imbobo ye-valve eyakhelwe ngaphakathi noma imbobo ye-valve yangaphandle ingakhiqizwa; Imbobo yevalve emise okwe-barrel kanye nembobo ye-valve yesithupha ingakhiqizwa.

Shintsha amapharamitha esibukweni ukuze usethe ubude bephepha lembobo yesivalo.

● Indlela yokuqinisa yangaphakathi*

Indlela yokulungisa iqondisa iphepha eliqinisayo endleleni efanele.Bese iphepha lidlulisa indlela yokudonsa kanye nokusika emgqeni wokugoqa kanye ne-pinch roll. Iphepha eliphiniwe yi-pinch roll lihamba ngesondo leglue bese linamathiselwa esikhwameni.

Uhlelo lokulawula ngogesi lucubungula inqubo. Uma singekho isikhwama esikuso, isistimu yokulawula izokhansela iphepha lokumpintsha ukuze iphepha linganamathiseli futhi lithunyelwe endaweni yokuphuma. Futhi isondo leglue lizohlukana ne-pinch roll.

Ifakwe idivayisi yokulungisa umehluko, ingalungisa ngokuguquguqukayo indawo ye-tape yephepha ngaphandle kokumisa umshini.

Shintsha amapharamitha esibukweni ukuze usethe ubude bephepha lembobo yesivalo.

● Indlela yokuvala engezansi kanye ne-gluing

Ifakwe idivayisi yokuhlehlisa ngezansi yesikhwama sephepha ukusiza ukwakheka okungaphansi.

Ifakwe idivayisi enkulu yamasondo eglue.Ngokuvumelana nezicaciso ezihlukene zosayizi wesikhwama sephepha kanye nezidingo zenqubo, shintsha kalula ukuma kwepuleti lerabha.

Ifakwe uhlelo lokuhlukanisa.Uma kutholwa ukuthi alikho ishubhu lephepha esiteshini sokudlulisa noma indawo engezansi yeshubhu yephepha ayivuliwe, uhlelo lokuhlukanisa luzoshiya ngokuzenzakalelayo isondo leglue elikhulu, ngakho-ke ishubhu lephepha ngeke linamathele.

● Indlela yokwenza isikhwama

Ithuluzi lokwakha lakhiwe ngamapuleti angaphakathi aphezulu naphansi angaphakathi nangaphezulu nangaphansi.

amapuleti angaphakathi angaphandle.Iphiko lesikhwama lisekelwa ibhodi elingaphakathi elingaphakathi, futhi ibhodi elingaphakathi elingaphandle liqondiswa ukuze ligoqe futhi lenze iphansi eliyisikwele, ukwenza ukunamathisela kuqine ngokwengeziwe ngesondo lokuhlanganisa.

Ubukhulu bamabhodi asemqoka angaphezulu naphansi angalungiswa ngokuya ngezidingo zokukhiqiza zamasayizi aphansi esikhwama sephepha ahlukene.

● Indlela yokubuyekeza ezansi

Iphansi lesikhwama limile ngemva kokunamathiselwa. Ukuze kuhlanganiswe kangcono nokudlulisa okweqile, okuphansi kwesikhwama kudinga ukugoqwa nge-engeli engama-degree angu-90 ukuze kulingane umzimba wesikhwama. Ibha yokuphequlula &eqondisayo phezulu naphansi ukuze wenze isiphansi sesikhwama sibe sicaba kancane sibe yibhande elibambayo lokuhambisa.

● Indlela yokubala nokubala*

Isikhwama sephepha singena ebhandeni le-slow speed compaction, futhi umphumela wokuhlanganisa ubonakala ngokucacile ngemva kokupakisha.

Ifakwe idivayisi yokubala, inombolo yokufakwa ngaphambilini yezikhwama zamaphepha zingasethwa ngokuhlelekile.

Ifakwe i-vacuum adsorption kanye nedivayisi yokuhlukanisa esheshayo, esetshenziselwa ukuhlukanisa izikhwama zephepha ezipakishiwe ngemva kokufinyelela inombolo yezikhwama zephepha ezibekwe uhlelo.

● Indlela yokukhipha

Uma kungena indlela yokuphuma esikhwameni, izikhwama zinqwabelana endaweni yokunqwabelanisa. Ngemuva kokuthi inani lezikhwama zephepha lifinyelele inani elifakiwe ngaphambilini, i-valve yendawo yokunqwabelanisa iyavuleka, futhi ibhande elingaphansi liqala ukudlulisa. Bese kuthi izikhwama zamaphepha ezipakishiwe zithuthelwe endaweni yokuqoqwa kwezikhwama, bese izikhwama zamaphepha zifakwe amaphalethi ngabasebenzi.