I-LQ FM2018 Umshini Owodwa Wekhanda Eliphansi

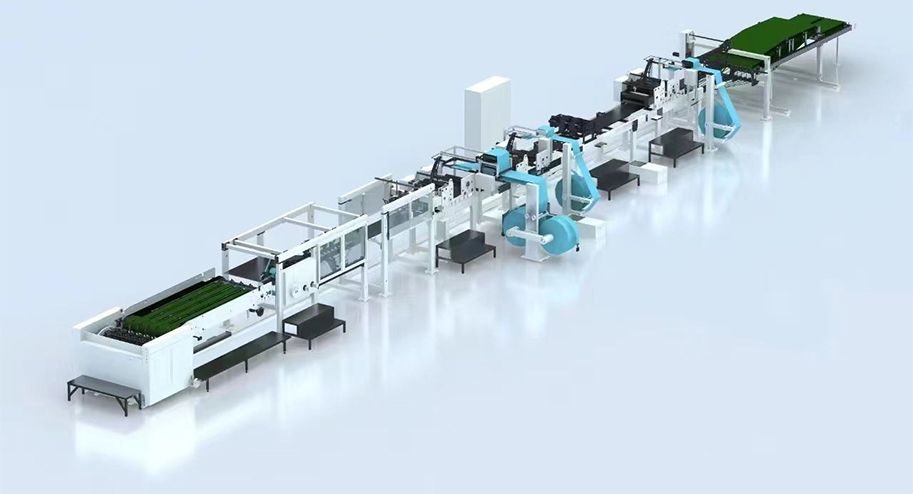

Isithombe somshini

● Ingakwazi ukusingatha izendlalelo zephepha ezingu-2-4.

● Ukwazi ukukhiqiza isikhwama sephepha esisodwa esivaliwe. Faka isikhwama esivaliwe ohlangothini olulodwa emshinini bese ukhiqiza isikhwama esivaliwe esiseceleni okukabili.

● Ngokuqiniswa kwangaphakathi kanye nendlela yokuqinisa yangaphandle.

● Ikwazi ukukhiqiza isikhwama sephepha se-valve esingaphansi esiyisikwele, isikhwama se-valve esikhulu se-sonic, nesikhwama esingaphansi esiyisikwele esiyiphepha seplastiki.

| Uhlobo Lomshini | I-LQ FM2018 |

| Ubude besikhwama(Isikhwama esinamathiselwe ikhanda elikabili)(mm) | 365-850 |

| Ububanzi besikhwama(mm) | 350-600 |

| Ububanzi besikhwama esingezansi(mm) | 90-200 |

| Isivinini esikhulu sokuklama(izikhwama/umzuzu) | 100 |

| Usayizi womshini(m) | 28.72X5.2X2.3 |

| Amandla | 30kw |

● Isistimu yokudlulisa okuphakelayo

Indlela yokondla i-Rotary roller. I-roller encane izungeza i-roller enkulu, futhi ngesikhathi esifanayo ijikeleze ngokuhlehla ukuze imunce ishubhu lephepha. Irola elikhulu lingakwazi ukumunca amashubhu ephepha angu-8 ukuze lizungezise umzuliswano owodwa.

Indlela yokuphakela iplanethi yokuzungeza i-vacuum inendlela elula, umsebenzi othembekile kanye nokudla okuzinzile.

Ifakwe idivayisi yokuhlela nokubeka ukuze kuqinisekiswe ukunemba kwendawo ezungeze isilinda sesikhwama sephepha engena enqubweni elandelayo.

● Indlela yokuhlehlisa & yokusika eqondile

Ifakwe umsebenzi we-oblique indentation, indawo ye-oblique indentation ingalungiswa ngaphandle kokumisa umshini.

Ifakwe umsebenzi wokusika oqondile, osetshenziswa ikakhulukazi enqubweni yokunamathisela-phansi yamashubhu e-flat cutting paper.Sika imilomo emibili yesikhwama sephepha ngesikhathi esisodwa.

Shintsha amashubhu ephepha ukusuka kokuvundlile ukuya kokuqondile.

● Vula indlela yokwenza isicaba

Ifakwe i-vacuum suction mechanism, esetshenziselwa ukuvula umlomo wamashubhu ephepha, ukuze uphondo lomshini lufakwe kahle emlonyeni wamashubhu ephepha.

Ifakwe umshini wophondo, ukuze uvule umlomo wezikhwama zephepha futhi ulenze libe ngesimo sedayimane esilinganayo.

Ifakwe umshini wokucaba ukuze usize i-horm ukuthi yakhe phansi isikhwama sephepha, futhi ihlanganise isakhiwo esimise okwedayimane ngaphansi kwesikhwama sephepha.

● Indlela yevalvu

Indlela yokulungisa iqondisa iphepha lokuqinisa endleleni efanele. Khona-ke iphepha lidlulisela indlela yokudonsa kanye nokusika emgqeni wokugoqa kanye nomqulu wokuncinza. Iphepha eliphiniwe yi-pinch roll lihamba ngesondo leglue bese linamathiselwa esikhwameni.

Ingafakwa embotsheni ye-valve yephepha yangaphandle noma eyakhelwe ngaphakathi, ifilimu yesiqeshana sephepha engaqondani kahle nembobo yevalvu eyakhelwe ngaphakathi.

Ifakwe umshini wokuhlukanisa, ongalungisa indawo yamashubhu ephepha nephepha afakwe ku-inthanethi.

Shintsha amapharamitha esibukweni ukuze usethe ubude bephepha lembobo yesivalo.

● Ukuqiniswa kwangaphakathi kwesikhungo

Indlela yokulungisa iqondisa iphepha eliqinisayo endleleni efanele.Bese iphepha lidlulisa indlela yokudonsa kanye nokusika emgqeni wokugoqa kanye ne-pinch roll. Iphepha eliphiniwe yi-pinch roll lihamba ngesondo leglue bese linamathiselwa esikhwameni.

Uhlelo lokulawula i-elekthronikhi lucubungula inqubo. Uma singekho isikhwama esimeni, isistimu yokulawula izokhansela iphepha lokumpintsha ukuze iphepha linganamathiseli futhi lizothunyelwa lapho kuphuma khona. Futhi isondo leglue lizohlukana ne-pinch roll.

Ifakwe idivayisi yokulungisa umehluko, ingalungisa ngokuguquguqukayo indawo ye-tape yephepha ngaphandle kokumisa umshini; Shintsha amapharamitha esibukweni ukuze usethe ubude bephepha lembobo yesivalo.

● Indlela yokuhlehlisa &yokuvala ngezansi &nokwakheka

Ifakwe idivayisi yokuhlehlisa ngezansi yesikhwama sephepha ukusiza ukwakheka okungaphansi; Ifakwe idivayisi enkulu yamasondo eglue.Ngokuvumelana nemininingwane ehlukene yesayizi yesikhwama sephepha kanye nezidingo zenqubo, shintsha kalula ukuma kwepuleti lerabha;

Ithuluzi lokwakha lakhiwa amapuleti angaphakathi aphezulu naphansi angaphakathi kanye namapuleti angaphandle aphezulu nangaphansi, futhi iphiko lephepha elingaphansi kwesikhwama lisekelwa ipuleti elingaphakathi elingaphakathi, futhi ibhodi elingaphakathi elingaphandle liqondiswa ukuze ligoqe futhi liwohloke ukuze libe isikwele esingezansi, esinamathiselwe ngokuqinile isondo elihlanganisayo.

Ubukhulu bamabhodi asemqoka angaphezulu naphansi angalungiswa ngokuya ngezidingo zokukhiqiza zamasayizi aphansi esikhwama sephepha ahlukene.

● Izikhungo zokuqinisa zangaphandle

Indlela yokulungisa iqondisa iphepha lokuqinisa endleleni efanele. Khona-ke iphepha lidlulisela indlela yokudonsa kanye nokusika emgqeni wokugoqa kanye nomqulu wokuncinza. Iphepha eliphiniwe yi-pinch roll lihamba ngesondo leglue bese linamathiselwa esikhwameni.

Ifakwe idivayisi yokulungisa umehluko, ingalungisa kalula indawo ye-tape yephepha ngaphandle kokumisa umshini.

Shintsha amapharamitha esibukweni ukuze usethe ubude bephepha lembobo yesivalo.

Ifakwe indlela egcwele yokudla yephepha le-servo enenzwa yombala, enemodi yokusika uphawu lombala kanye nemodi yokusika ubude obumisiwe. Shintsha amapharamitha esikrinini.

● Indlela yokuphetshwa phansi

Iphansi lesikhwama limile ngemva kokunamathiselwa nje. Ukuze uthole ukuminyana okungcono nokudlulisa okugqagqene, iphansi lesikhwama lidinga ukuphetshwa nge-engeli engu-90-degree ukuze lilingane nomzimba wesikhwama. Ibha yokuphequlula &eqondisayo phezulu naphansi ukuze wenze isiphansi sesikhwama sibe sicaba kancane sibe yibhande elibambayo lokuhambisa.

● Indlela yokuhlanganisa nokukhiphayo

Isikhwama sephepha singena ebhandeni le-slow speed compaction, futhi umphumela wokuhlanganisa ubonakala ngokucacile ngemva kokupakisha.

Ifakwe idivayisi yokubala, inombolo yokufakwa ngaphambilini yezikhwama zamaphepha zingasethwa ngokuhlelekile.

Ifakwe i-vacuum adsorption kanye nedivayisi yokuhlukanisa esheshayo, esetshenziselwa ukuhlukanisa izikhwama zephepha ezipakishiwe ngemva kokufinyelela inombolo yezikhwama zephepha ezibekwe uhlelo.

Izikhwama zephepha zihlukaniswa endaweni yokuqoqa izikhwama, futhi opharetha banamathisele izikhwama zephepha eziwile.