LQ FM2018 Umatshini omnye wentloko ephantsi

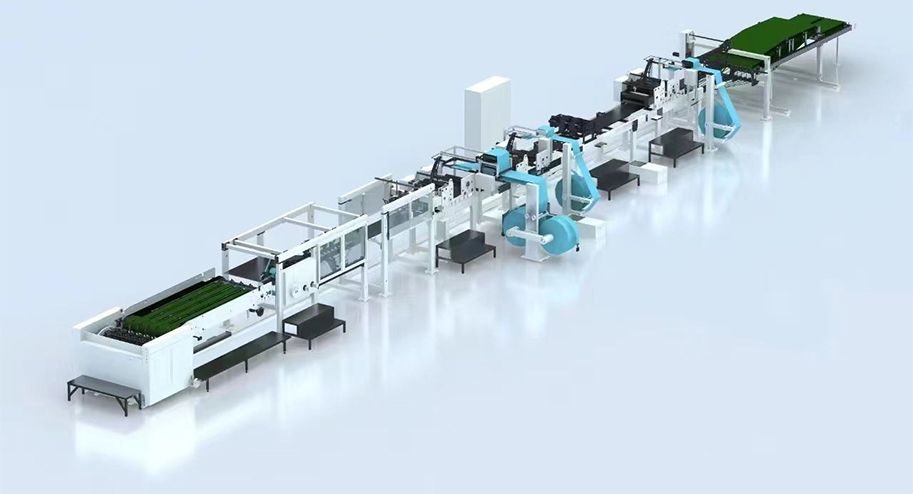

Ifoto yomatshini

● Unokuphatha iileya zephepha ezi-2-4.

● Ukwazi ukuvelisa ingxowa yephepha enye evaliweyo. Yondla icala elinye ibhegi evaliweyo kumatshini emva koko unokuvelisa ibhegi evaliweyo emacala amabini.

● Ngokomelezwa kwangaphakathi kunye nendlela yokuqinisa yangaphandle.

● Iyakwazi ukuvelisa ibhegi yephepha yevalve yesikwere esezantsi, ibhegi yevalve ephezulu ye-sonic, kunye nengxowa esezantsi yeplastiki yesikwere.

| Uhlobo lomatshini | LQ FM2018 |

| Ubude bebhegi(Intloko ephindwe kabini ibhegi encamathelisiwe)(mm) | 365-850 |

| Ububanzi bengxowa (mm) | 350-600 |

| Ibhegi esezantsi ububanzi(mm) | 90-200 |

| Ubukhulu besantya soyilo(iingxowa/imiz) | 100 |

| Ubungakanani bomatshini(m) | 28.72X5.2X2.3 |

| Amandla | 30kw |

● Isixhobo sokuhambisa isondlo

Indlela yokutya i-Rotary roller. I-roller encinci ijikeleza i-roller enkulu, kwaye kwangaxeshanye ijikeleze ngasemva ukuze ithathe ityhubhu yephepha. Irola enkulu inokufunxa iityhubhu zephepha ezisi-8 zokujikeleza umjikelo omnye.

Indlela yokufunxa ngeplanethi ijikelezisa ivacuum ineyona ndlela ilula, umsebenzi othembekileyo kunye nokutya okuzinzileyo.

Ukuxhotyiswa nge-orting kunye nokubekwa kwesixhobo sokulungelelanisa ukuqinisekisa ukuchaneka kwendawo ejikeleze i-cylinder yesikhwama sephepha engena kwinkqubo elandelayo.

● I-Indent & indlela yokusika ngokuthe ngqo

Ukuxhotyiswa nge-oblique indentation function, indawo ye-oblique indentation inokulungiswa ngaphandle kokumisa umatshini.

Ukuxhotyiswa ngomsebenzi wokusika ngokuthe ngqo, ngokukodwa kusetyenziswe kwinkqubo yokunamathisela-ezantsi ye-flat cutting paper tubes.Sika imilomo emibini yesikhwama sephepha ngexesha elifanayo.

Guqula iityhubhu zephepha ukusuka kokuthe tye ukuya nkqo.

● Vula &iphondo indlela yokuthambisa

Ixhotyiswe nge-vacuum suction mechanism, esetyenziselwa ukuvula umlomo wemibhobho yephepha, ukuze uphondo lwe-mechanical lufakwe kakuhle emlonyeni wemibhobho yephepha.

Ixhotyiswe ngomatshini wesigodlo, ukuvula umlomo weengxowa zephepha kwaye wenze kwi-symmetrical diamond shape.

Ixhotyiswe ngomatshini wokucanda ukuncedisa ihorm ukuba yenze umzantsi wesikhwama sephepha, kwaye idibanise isakhiwo esifana nedayimani ezantsi kwesikhwama sephepha.

● Indlela yevalvu

Indlela yokulungisa iqondisa iphepha lokuqinisa kwindlela elungileyo. Emva koko iphepha lidlulisa i-traction kunye nendlela yokusika kwi-roll roll kunye ne-pinch roll. Iphepha elifakwe yi-pinch roll lihamba ngevili leglue kwaye lifakwe kwisikhwama.

Inokufakwa kwiphepha elinye langaphandle okanye ivalvu eyakhelwe-ngaphakathi kwizibuko, ifilimu yekliphu yephepha engalungelelanisiweyo eyakhelweyo kwizibuko levalvu.

Ixhotyiswe ngeendlela ezahlukeneyo, ezinokuthi zilungelelanise indawo yephepha elifakiweyo kunye neetyhubhu zephepha kwi-intanethi.

Guqula iiparameters kwisikrini ukuseta ubude bephepha levalve yesibuko.

● Uqinisekiso lwangaphakathi lweziko

Indlela yokulungisa iqondisa iphepha lokuqiniswa kwindlela efanelekileyo.Emva koko iphepha lidlulisa i-traction kunye nendlela yokusika kwi-roll roll kunye ne-pinch roll. Iphepha elifakwe yi-pinch roll lihamba ngevili leglue kwaye lifakwe kwisikhwama.

Inkqubo yokulawula i-Elecronic iphonononga inkqubo. Ukuba akukho bhegi ikwindawo, inkqubo yolawulo iya kurhoxisa iphepha lokutsiba ukuze iphepha lingancanyathiselwe kwaye liya kuthunyelwa kwindawo yokuphuma. Kwaye ivili leglue liya kuhlukana ne-pinch roll.

Ukuxhotyiswa ngesixhobo sokuhlengahlengisa ukwahlula, kunokulungelelanisa ngokuguquguqukayo indawo yetape yephepha ngaphandle kokumisa umatshini; Guqula iiparameters kwisikrini ukuseta ubude bephepha levalve yesibuko.

● Indlela yokuma phakathi kunye nokuvala ezantsi &ukwenza indlela

Ixhotyiswe ngengxowa yephepha isixhobo sokujongwa ezantsi ukuncedisa ukwenza umzantsi; Ixhotyiswe ngesixhobo esikhulu sevili leglu.Ngokuhambelana nemigangatho eyahlukeneyo yengxowa yephepha kunye neemfuno zenkqubo, utshintshe ngokuguquguqukayo ubume bepleyiti yerabha;

Isixhobo sokubumba siqulunqwe ngamacwecwe angaphakathi aphezulu nangaphantsi kunye namacwecwe angaphezulu nangaphantsi angaphandle, kwaye iphiko lephepha elisezantsi kwesikhwama lixhaswa yi-plate yangaphakathi yangaphakathi, kunye nebhodi yangaphandle engundoqo ikhokelwa ukuba igobe kwaye ikhubaze ukwenza i-square ezantsi, egxininiswe ngokuqinileyo ngevili elidibanisayo.

Ubungakanani beebhodi eziphezulu kunye nezisezantsi zinokulungelelaniswa ngokweemfuno zemveliso yeengxowa zephepha ezahlukeneyo.

● Amaziko oqinisekiso angaphandle

Indlela yokulungisa iqondisa iphepha lokuqinisa kwindlela elungileyo. Emva koko iphepha lidlulisa i-traction kunye nendlela yokusika kwi-roll roll kunye ne-pinch roll. Iphepha elifakwe yi-pinch roll lihamba ngevili leglue kwaye lifakwe kwisikhwama.

Ixhotyiswe ngesixhobo sokulungelelanisa umahluko, inokulungelelanisa ngokuguquguqukayo indawo yeteyiphu yephepha ngaphandle kokumisa umatshini.

Guqula iiparameters kwisikrini ukuseta ubude bephepha levalve yesibuko.

Ixhotyiswe ngenkqubo epheleleyo yokutya ye-servo ene-sensor yombala, enemodi yokusika uphawu lombala kunye nemodi yokusika ubude obusisigxina. Guqula iiparameters kwiscreen.

● Indlela yokujikela ezantsi

Umzantsi webhegi ume nkqo emva kokuncamathisela nje. Ukulungelelaniswa okungcono kunye nokugqithisa okugqithisiweyo, umzantsi webhegi kufuneka ujikwe kwi-angle ye-90-degree ukuze ulungele umzimba webhegi. Ukuphetshetheza &ibhanti ekhokelayo phezulu nasezantsi ukuthoba ngobunono umzantsi webhegi kwibhanti yokuhambisa.

● Indlela yokudibanisa kunye nemveliso

Isikhwama sephepha singena kwi-speed speed compaction belt, kwaye umphumo wokudibanisa ubonakala ngokucacileyo emva kokupakisha.

Ukuxhotyiswa ngesixhobo sokubala, inani lokufakela kwangaphambili leengxowa zephepha lokubala lingamiselwa ngokucwangcisiweyo.

Ixhotyiswe nge-vacuum adsorption kunye nesixhobo sokwahlula ngokukhawuleza, esisetyenziselwa ukwahlula iingxowa zephepha ezipakishwe emva kokufikelela kwinani leengxowa zephepha ezibekwe yinkqubo.

Iingxowa zephepha zohlulwe kwiqonga lokuqokelela iingxowa, kwaye abaqhubi baphalelisa iingxowa zephepha eziwileyo.