Single facer corrugation machine

Machine Photo

Apply Photo

Hydraulic Shaftless Mill Roll Stand

● Symmetrical structure, may clamp two scroll at the same time, may load or unload scroll without stop the production.

● Hydraulic control. Lifting and lowering, open-close and right-right adjustments of arms are operated by hydraulic system.

● Pneumatic control of the web tension.

● The paper chuck adopt expansion type.

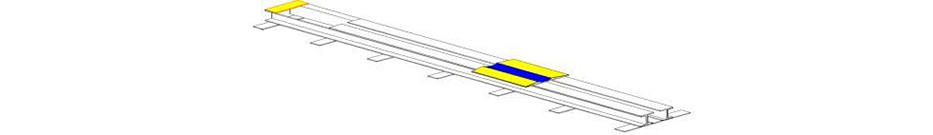

Railing and Track

● Moving paper roll, light and flexible.

● Rail way is on the ground, main structure is welded with 16# steel, firm and durable.

● Upper steel plate will be welded when it is assembled.

● Each set of mill roll stand consists of two sets of railing for reels.

Pre-Heater

● Each roller surface is well whetted and chrome plated, sooth and durable.

● Electro motion adjust the dimension of pre-heater, the range of adjustment: 60-270 °.

● The pre-heating roller is made according to national container safety standard.

● Pre-heating roller and guiding paper roller are electically galvanized.

● Electro motion adjust the dimension of pre-heater, suitable with different grades of paper and machinery speed.

320D Single Facer

● Cardboard transmitting method adopts wind absorption, and keep flute profiles stable under the running condition of high speed.

● The wind machine absorbs corrugated paper to corrugated rollers through vacuum box and form corrugated profile.

● The width of wind groove of lower roller is not exceeding 2.5mm,and will less fringe marks of single corrugated paperboard.

● Transmission part adopt gimbal transmission, away from vibration source, and make the transmission more steady and reliable, and easy to maintain.

● The speed reducing box is oil-lubricating, close gear transmission, and will reduce machine vibration.

● Glue unit adopts auto-supply glue circularly, pneumatically reset and has buffering effect.

● Glue area will be electrically adjusted, glue unit can be running independently when machine steppes, and prevent glue running out.

● Upper corrugated roller surface are treated by special mesh snicked and chrome plated.

● Glue unit independent drive, pump-draw style, easy maintain and clean.

● Corrugated forming unit is designed with small independent wall plate. The roller is easy to disassembly, maintain, and quickly change flute profiles.

● Upper-lower corrugated roller are made of high quality 48CrMo alloy steel, and after heat-treatment, the rigidity is HRC 55-62, the surface are grinded and plated chrome.

Bridge Conveyor

● The single-sided corrugated single machine processed accurately through transmission belt to the bridge using the reserve for the next process.

● Department of traction speed and single machine synchronous control by frequency conversion.

NC Slitter Scorer with Cut-Off

● Synchronous control, cutter speed is strictly in synchronization with the speed of single facer.

● Jifeng tungsten steel thin knife is featured by automatic grinding, long service life of blade and high slitting quality.

● Independent servo control for longitudinal knife arrangement, which is quick, accurate and reliable.

● Longitudinal cutting speed is controlled by frequency convertor and adjusted synchronously according to paperboard speed.

● Standard waste absorption port, the position of left and right ports is adjusted automatically according to edge cutter during replacement.

● Fuji AC servo motor, server.

● All low-voltage apparatuses are Schneider.

● The box and base are made from excellent castings that can ensure strict aging, precise machining and long-term and stale equipment operation.

● Alloy steel cutter shaft that can ensure precise machining, dynamic balancing, high rigidity and small inertia.

● Precise alloy steel gearing and serrated blade, stable, tidy and accurate paper cutting.

● Cross cutting is controlled by AC PMSM and AC servo controller to ensure highly accurate cross cutting and high efficiency.

● Automatic replacement, replacement connector with automatic insertion removal.

● Standard reservoir capacitance and impedance, stable and energy-saving cross cutter.

● Precise NSK and IKO bearings imported from Japan with original packaging.

● Super wear-resistance and low-noise gears imported from Taiwan.

● There is no need to replace bearing within 10 years.

Automatic Hanging Basket Stacking Machine

● 4-segment belt transport, stacking with hanging basket, accurate counting, automatic stack change, tidy stacking.

● Dynamic sandwich conveyor belt at first segment, the clearance between upper and lower belts can be adjusted manually.

● Stable overlaying transport of paperboards, at the second and third segments; automatic transport speed adjustment during stack change and order replacement.

● Double dynamic transport belts at fourth segment; automatic placing of upper transport belt.

● Paperboard transport controlled by CPG reducing motor and frequency converter; synchronous transport speed and paperboard speed.

● Accurate counting, automatic stack change and quick and accurate order replacement.

● Belt-type hanging basket stacking platform; stable lifting of hanging basket platform controlled by AC servo.

● Paperboard alignment belt is controlled by AC servo to prevent paperboard warpage and align paperboards with the rear stop plate.

● Rear stop plate is controlled and positioned by AC servo to realize quick and accurate adjustment during order replacement.

● When stacking reached the set quantity, paperboards will be output stably and crossly at variable frequency.

● Standard non-dynamic roll paper holder that can facilitate direct tumbling and stacking.

| Max. Mechanical Speed | 150m/min |

| Production Line Length | About 27meters |

| Flute Profiles | A,C,B,E flute |

| Total Power | 3 Phase 380v 50hz 92kw |

● Our knowledge and expertise in the industry allow us to create products that meet or exceed your expectations.

● We are always committed to product quality control, focus on technology research and development and innovation, strengthen the concept of service, step by step.

● Our Single Facer Corrugated Board Production Line is of the highest quality and is available at a competitive price.

● Our outstanding performance in the professional field has won the favor and trust of many enterprises.

● We guarantee that our Single Facer Corrugated Board Production Line will meet or exceed your expectations.

● We have been committed to the development and sales of Corrugator Single Facer at home and abroad.

● Our company is committed to delivering exceptional products and services that exceed your expectations.

● Looking ahead, we will always carry out the quality policy of establishing integrity consciousness and building high-quality Corrugator Single Facer.

● We understand that every customer is unique, and that's why we offer personalized solutions to fit your needs.

● The ability to develop independently allows us to be free from other constraints.