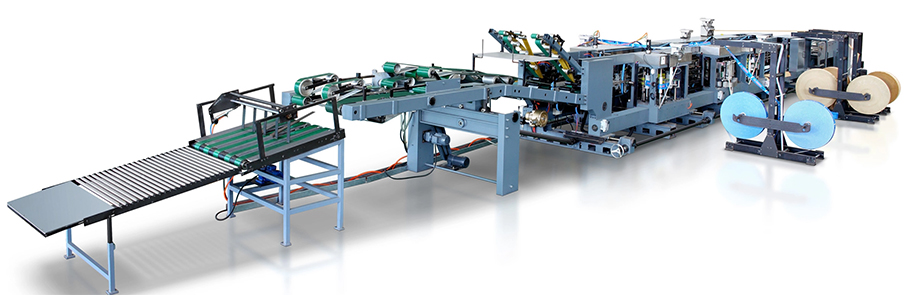

LQ HD8916 Makina Apansi

Chithunzi cha Makina

Itha kunyamula mapepala 2-4:

● Kutha kutulutsa mbali imodzi yotsekedwa, mbali imodzi yotsegula thumba.

● Ndi kulimbikitsa kwamkati ndi njira yowonjezera yowonjezera (posankha).

● Amatha kupanga thumba limodzi wosanjikiza valavu pepala thumba, cylindrical kunja valavu pepala thumba, pansi chachikulu ndi thumba laling'ono valavu pepala, kunjathumba valavu ndi kusiyana chala chachikulu, ndi super sonic vavu thumba.

| Mtundu wa Makina | LQ HD8916 |

| Utali wa thumba (mm) | 370-770 |

| Kukula kwa thumba (mm) | 350-550 |

| Chikwama pansi m'lifupi (mm) | 90-160 |

| Chikwama chapakati mtunda (mm) | 280-620 |

| Kuthamanga kwapamwamba kwambiri | 150strip/mphindi 150tubes/mphindi |

● Njira yodyetsera

Rotary wodzigudubuza kudyetsa njira.Wodzigudubuza yaing'ono amazungulira mozungulira lalikulu wodzigudubuza, ndipo nthawi yomweyo atembenuza mosintha kuyamwa pepala chubu. Chogudubuza chachikulu chimatha kuyamwa machubu 8 a mapepala pozungulira kuzungulira kumodzi.

Mapulaneti ozungulira vacuum kuyamwa njira yodyetsera ili ndi njira yosavuta, ndipo ndiyodalirika komanso yokhazikika.

● Kusankha ndi kung'ambika

Okonzeka ndi malo chipangizo kuonetsetsa kulondola kwa malo a machubu mapepala polowa wotsatira ndondomeko.

Wokhala ndi chipangizo cholumikizira oblique, malo a oblique indentation amatha kusinthidwa popanda kuyimitsa makina.

Okonzeka ndi ntchito ya puncturing dzenje utsi, makamaka ntchito kupanga simenti mapepala matumba.Can puncture kudzera thumba lonse, ndi kuboola singano manja angachotsedwe mwamsanga.

Okonzeka ndi ntchito molunjika kudula mpeni, kudula masamba awiri mbali ziwiri za thumba pepala, makamaka ntchito phala-pansi ndondomeko kupanga lathyathyathya kudula pepala machubu.

● Tsegulani & nyanga kufunthitsa makina

Okonzeka ndi vacuum suction mechanism, yomwe imagwiritsidwa ntchito potsegula pakamwa pa machubu a mapepala, kuti nyanga ya makinawo ilowetsedwe m'kamwa mwa mapepala a mapepala.

Okonzeka ndi nyanga limagwirira, kutsegula pakamwa matumba mapepala ndi kupanga mu symmetrical diamondi mawonekedwe.

Okonzeka ndi njira yosalala yothandiza nyanga kupanga pansi pa thumba la pepala, ndikugwirizanitsa mawonekedwe a diamondi pansi pa thumba la pepala.

● Flake valve port mechanism*

Makinawa amadula tepi ya pepala la vavu kuti apange pepala la valve, ndikuyika pepala la valve pamatumba.

Angathe kupanga valavu kunja kapena anamanga-mu wosanjikiza pepala, ndi pepala filimu misaligned anamanga-valavu.

Ili ndi makina osiyanitsa, omwe amatha kusintha momwe pepala la valavu yoyikidwira popanda kuyimitsa makinawo.

Sinthani magawo pazenera kuti muyike kutalika kwa pepala la valve.

● Cylindrical valve port mechanism*

Makinawa amadula tepi ya pepala la vavu kuti apange pepala la valve, kenaka pindani ndi kumata pepalalo kuti mupange chubu.

Wokhala ndi chida chosinthira chosiyana, tepi yamapepala imatha kusinthidwa mosavuta popanda kuyimitsa makina;

Doko la valavu lomangidwa mkati kapena doko lakunja la vavu lingapangidwe; Khomo la valve yooneka ngati mbiya ndi khomo la valavu ya thumb-gap litha kupangidwa.

Sinthani magawo pazenera kuti muyike kutalika kwa pepala la valve.

● Internal reinforcement mechanism*

Makina owongolera amawongolera pepala lolimbikitsira kunjira yoyenera. Kenako pepalalo limadutsa njira yokokera ndikudula ku mpukutu wopindika ndi kutsina mpukutu. Mapepala otsinikizidwa ndi mpukutuwo amadutsa mu gudumu la guluu ndiyeno amaikidwa pa thumba.

Electronic Control System imayang'anitsitsa ndondomekoyi. Ngati palibe thumba lomwe lili pamalopo, makina owongolera amaletsa mapepala otsina kuti pepalalo lisamangiridwe ndipo litumizidwa kumalo otuluka.

Okonzeka ndi chipangizo chosinthira masiyanidwe, amatha kusintha mawonekedwe a tepi yamapepala popanda kuyimitsa makinawo.

Sinthani magawo pazenera kuti muyike kutalika kwa pepala la valve.

● Kutsekera pansi ndi makina omatira

Okonzeka ndi pepala thumba pansi indentation chipangizo kuthandiza pansi kupanga.

Okonzeka ndi gudumu lalikulu la guluu device.Malinga ndi kukula kwa thumba la mapepala ndi zofunikira za ndondomeko, sinthani kusintha mawonekedwe a mbale ya rabala.

Okonzeka ndi dongosolo kulekana.Zikadziwika kuti palibe pepala chubu pa siteshoni yotumizira kapena pansi pa pepala chubu si lotseguka, dongosolo kulekana basi kusiya lalikulu guluu gudumu, kotero pepala chubu si glued.

● Njira yopangira thumba

Chipangizo chopangiracho chimapangidwa ndi mbale zam'mwamba ndi zapansi zamkati komanso kumtunda ndi kumunsi.

mapiko akunja apakati.Phiko la thumba limathandizidwa ndi bolodi lamkati lamkati, ndipo bolodi lakunja lapakati limatsogozedwa kuti lipinde ndi kupanga pansi lalikulu, kuti phala likhale lolimba kwambiri kudzera mu gudumu lophatikizana.

Kukula kwa matabwa apamwamba ndi apansi angasinthidwe molingana ndi zofunikira zopangira zosiyana siyana zamapepala pansi.

● Njira yosinthira pansi

Pansi pa chikwamacho ndi choyimirira pambuyo pa kuphatikizika. Kuti muphatikize bwino ndikudutsana, pansi pa chikwamacho pamafunika kufinyidwa pamakona a digirii 90 kuti zigwirizane ndi thumba. Kutembenuzira &kulondolera kapinga m'mwamba ndi pansi kuti pansi pa chikwama muphwanyike pang'onopang'ono kukhala lamba wolumikizira.

● Njira yophatikizira ndi kuwerengera*

Chikwama cha pepala chimalowa mu lamba wapang'onopang'ono wothamanga, ndipo compaction effect imakhala yowonekera kwambiri pambuyo pa stacking.

Okonzeka ndi kuwerengera chipangizo, preinstall chiwerengero cha kuwerengera mapepala mapepala akhoza kukhazikitsidwa mwadongosolo.

Okonzeka ndi vakuyumu adsorption ndi inapita patsogolo kulekana chipangizo, amene ntchito kulekanitsa zakhala zikuzunza m'miyoyo matumba pepala pambuyo kufika chiwerengero cha mapepala mapepala anapereka dongosolo.

● Makina otulutsa

Mukalowa m'makina otulutsira thumba, matumbawo amawunjikana m'malo osungira. Chiwerengero cha matumba a mapepala chikafika pamtengo wokonzedweratu, valavu ya stacking imatsegulidwa, ndipo lamba wapansi wa conveyor amayamba kusonyeza. Kenako matumba a mapepala owunjikidwawo amatengedwa kupita kumalo otolera matumbawo, ndipo matumba a mapepalawo amapakidwa pallet ndi antchito.