LQ ZT1962S Servo Tuber Machine

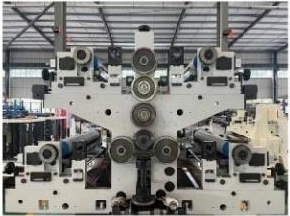

Machine Photo

| Machine Type | LQZT1962S |

| Stepped cul,tube ength(mm) | 500-1100 |

| Straight cut.tube length (mm) | 500-1100 |

| A-shaped edge,width(mm) | 350-620 |

| M-shaped edge,width(mm) | ≤80 |

| Cut | Straight+stepped |

| Layers | 2-4 layers of paper or 2-3 layers of paper+1 layer of PP or PE |

| Max design speed | 180 tubes/min |

| Max paper keel diameter(mm) | φ1300 |

| Size of the machine (m) | 28.72x2.38x2.875 |

| Power | 35KW |

● Printing section (optional).

● Four color printing;using flexible letterpress printing.

● To produce paper bags of different lengths,it is necessary to change the printing plate roller and the specification wheel; If the length of the paper tube is the same,only the printing offset plate needs to be replaced.

● Changing color need to clean the cartridge and the printing plate roller first; Use ceramic anilox roller to ink more evenly.

● When machine stops running, the printing plate roller will be jacked up by the cylinder, and the rubber plate and the printing plate roller will be separated to prevent the ink drying of the printing plate roller and the sticking of the paper.

● The machine group is equipped with 5 groups of paper roll holders, and the paper reel adopts air swelling shaft, which is convenient to operate and accurate positioning. Each paper holder is equipped with an axial adjustment device to adjust the paper roll to the correct position.

● Standard brake belt to control paper tension (magnetic powder brake control device can be added); Put the spare paper roll in the empty holder, and use adhesive tape to glue it with the paper roll that is about to run out,to realize fast paper change.

● The first paper roll holder is equipped with a guiding control device to locate the position of the paper tape.

● Keep the paper tape along the scheduled running path to ensure the accurate operation of the after process and stabilize product quality, thereby improving efficiency and saving materials.

● Adopt a four-layer structure, each layer is equipped with two parallel rollers, the rollers can be driven by servo motors according to a certain angle to move left and right, and equipped with sensors to detect the edge of the paper tape to control the position of the roller and then correct the position.