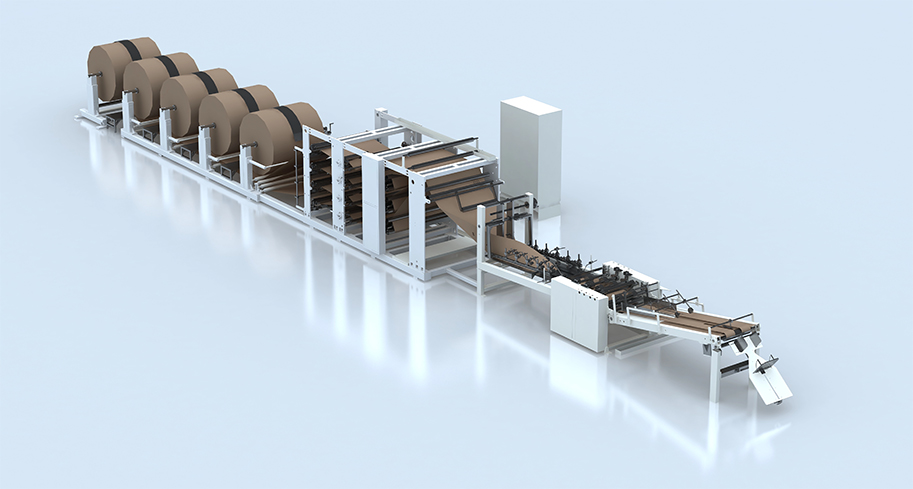

LQ YR2019 Flush Cut Servo Tuber Tshuab

Tshuab Duab

● Haum rau kev tsim cov hnab rau cov hmoov thiab cov khoom, xws li cov cement, mortar thiab tshuaj.

● Muaj peev xwm tsim tau A-zoo li txiav ntawv raj.

● Qhov hnyav ntawm cov ntaub ntawv yuav tsum nyob nruab nrab ntawm 70-100 g / m2.

● Muaj peev xwm tsim cov ntawv raj ua los ntawm 2-4 txheej ntawm daim ntawv lossis 2-3 txheej ntawm daim ntawv thiab 1 txheej ntawm PP lossis PE.

● Cov txheej txheem tseem ceeb yog tswj los ntawm servo system. Yooj yim hloov qhov parameter.

● Cov raj xa ntawv tuaj yeem siv rau ntawm lub tshuab hauv qab los tsim cov hnab ntawv.

| Tshuab Hom | LQ YR 2019 |

| Ncaj txiav ntev (mm) | 500-1100 Nws |

| A-shaped ntug dav (mm) | 350-620 : kuv |

| M-shaped ntug qhov tob (mm) | ≤80 |

| Txiav | Ncaj |

| Txheej | 2-4 txheej ntawm daim ntawv lossis 2-3 txheej ntawm ntawv + 1 txheej ntawm PP lossis PE |

| Max tsim ceev | 150 tubes / min |

| Max ntawv reel txoj kab uas hla (mm) | φ1300 |

| Qhov loj ntawm lub tshuab (m) | 18.5 x 2.35 x 2.08 |

| Hwj chim | 23 kWm |

● Cov pab pawg tshuab yog nruab nrog 5 pawg ntawm cov ntawv yob tuav, thiab daim ntawv reel txais cua swelling ncej, uas yooj yim rau kev khiav lag luam thiab qhov chaw raug. Txhua daim ntawv tuav yog nruab nrog cov cuab yeej hloov kho axial los kho cov ntawv yob mus rau txoj haujlwm raug.

● Txheem nres siv los tswj cov ntawv nro (sib nqus hmoov nres tswj cov cuab yeej tuaj yeem ntxiv); Muab cov ntawv yob rau hauv qhov khoob khoob khoob, thiab siv daim nplaum nplaum nplaum nrog cov ntawv yob uas tab tom yuav khiav tawm, kom paub cov ntawv hloov ceev.

● Thawj daim ntawv yob tuav yog nruab nrog cov cuab yeej tswj xyuas kom pom qhov chaw ntawm daim kab xev.

● Khaws daim ntawv daim kab xev raws li txoj hauv kev uas tau teem tseg kom paub tseeb tias qhov kev ua haujlwm raug ntawm cov txheej txheem tom qab thiab txhim kho cov khoom zoo, yog li txhim kho kev ua haujlwm thiab txuag cov ntaub ntawv.

● Txais yuav plaub-txheej qauv, txhua txheej yog nruab nrog cov kab xev, yog li ntawd cov ntawv xa tawm los txheeb xyuas qhov chaw uas yuav tsum tau los ntawm cov ntawv kom raug los ntawm lub hnab ntawv lub tog raj kheej.

● Qhia kev ua haujlwm ntawm txhua txheej ntawm daim kab xev, kho qhov sib txawv ntawm sab nraud, yooj yim rau kev khiav lag luam.

● Ntawm ob qhov kawg ntawm txoj kab tho (sab sauv thiab qis ntawm lub hnab ntawv lub tog raj kheej), ntau txheej ntawv daim kab xev yog glued los nplaum cov ntawv ntau txheej rau hauv ib txheej ntawm daim ntawv daim kab xev, kom lub tshuab gluing tom ntej tuaj yeem sib cais los ntawm txheej txheej sab hauv thaum qhib lub qhov ncauj ntawm lub hnab ntawv.

● Cov kauj ruam kab rov tav kua nplaum dispensing mechanism yog tsim los ntawm dispensing lub cev, kua nplaum rau cov menyuam thiab cov kua nplaum homogenizing.

● Lub dispensing lub cev yog nruab nrog ib ncig arc dispensing board, yas kev twb kev txuas mounted rau lub dispensing board thiab ib tug roj hmab taub hau, thiab txoj hauj lwm ntawm lub taub hau roj hmab tuaj yeem hloov kho kom haum rau cov ntawv raj xa dej ntawm cov kauj ruam sib txawv.

● Tus nqi ntawm cov kua nplaum tuaj yeem hloov kho los ntawm kev kho qhov sib txawv ntawm cov kua nplaum rau cov menyuam thiab cov kua nplaum nplaum lub cev, thiab cov roj hmab homogenizing cov menyuam.