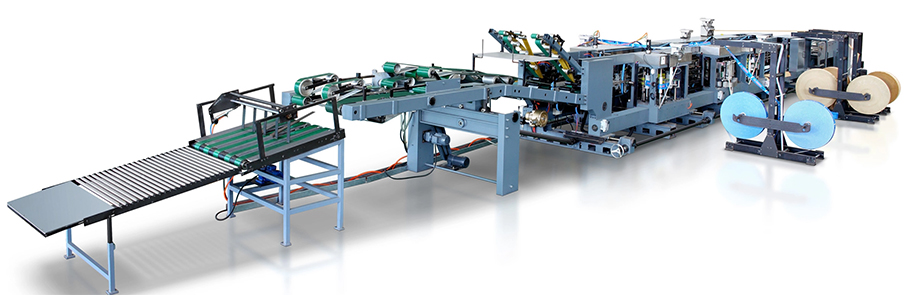

LQ HD8916 Bottomer Tshuab

Tshuab Duab

Tau lis 2-4 txheej ntawm daim ntawv:

● Muaj peev xwm tsim ib sab kaw, ib sab qhib lub hnab ntawv.

● Nrog rau kev txhawb nqa sab hauv thiab sab nraud cov cuab yeej txhawb nqa (yeem).

● Muaj peev xwm tsim ib txheej valve hnab ntawv, cylindrical sab nraud valve hnab ntawv, loj hauv qab thiab me me valve hnab ntawv, sab nraudvalve hnab nrog ntiv tes xoo, thiab super sonic valve hnab.

| Tshuab Hom | qw HD8916 |

| Hnab Length (mm) | 370-770 Ib |

| Hnab dav (mm) | 350-550 |

| Hnab hauv qab dav (mm) | 90-160 : kuv |

| Bag center nrug (mm) | 280-620 : kuv |

| Max tsim ceev | 150 strips / min 150 tubes / min |

● Pub mechanism

Rotary roller feeding method.Cov menyuam me rotates ib ncig ntawm cov menyuam loj, thiab tib lub sij hawm tig rov qab los nqus cov ntawv raj. Cov menyuam loj tuaj yeem nqus tau 8 daim ntawv raj rau tig ib puag ncig.

Planetary rotation nqus nqus plua plav mechanism muaj txoj kev yooj yim tshaj plaws, thiab txhim khu kev qha thiab ruaj khov.

● Soj tawm thiab perforation mechanism

Nruab nrog ib lub cuab yeej muab tso rau kom ntseeg tau qhov tseeb ntawm txoj hauj lwm ntawm cov hlab ntawv thaum nkag mus rau cov txheej txheem tom ntej.

Nruab nrog oblique indentation ntaus ntawv, txoj hauj lwm ntawm oblique indentation tuaj yeem hloov kho yam tsis tau nres lub tshuab.

Nruab nrog kev ua haujlwm ntawm pncturing tso lub qhov, feem ntau yog siv los ua cov hnab ntawv cement.Can puncture los ntawm tag nrho lub hnab, thiab lub tes tsho pierced tau sai sai.

Nruab nrog ncaj txiav riam muaj nuj nqi, txiav ob lub hniav nyob rau hauv ob qhov chaw ntawm lub hnab ntawv, feem ntau yog siv nyob rau hauv lub paste-hauv qab txheej txheem ntawm ua ca txiav cov hlab.

● Qhib & horn flattening mechanism

Nruab nrog lub tshuab nqus tsev nqus tsev vacuum, uas yog siv los qhib lub qhov ncauj ntawm cov ntawv raj, kom lub tshuab nqus tsev tuaj yeem muab tso rau hauv lub qhov ncauj ntawm cov ntawv raj.

Nruab nrog lub horn mechanism, qhib lub qhov ncauj ntawm lub hnab ntawv thiab ua rau nws nyob rau hauv ib tug symmetrical pob zeb diamond duab.

Nruab nrog ib tug flattening mechanism los pab lub horn rau hauv qab ntawm lub hnab ntawv, thiab compact lub pob zeb diamond-zoo li tus qauv nyob rau hauv qab ntawm lub hnab ntawv.

● Flake valve chaw nres nkoj mechanism *

Lub tshuab txiav lub valve daim kab xev los ua daim ntawv valve, thiab tom qab ntawd muab cov ntawv valve rau ntawm lub hnab.

Yuav ua rau sab nraud los yog built-in valve nrog ib txheej ntawm daim ntawv, thiab ntawv zaj duab xis misaligned built-in valve.

Nws muaj cov txheej txheem sib txawv, uas tuaj yeem kho txoj haujlwm ntawm daim ntawv ntxig valve yam tsis tas yuav tsum tau siv lub tshuab.

Hloov cov kev ntsuas ntawm qhov screen los teeb lub valve chaw nres nkoj ntawv ntev.

● Cylindrical valve chaw nres nkoj mechanism *

Lub tshuab txiav lub valve daim kab xev los ua daim ntawv valve, ces quav thiab nplaum daim ntawv los ua ib lub raj.Thiab thaum kawg muab cov ntawv valve rau ntawm lub hnab;

Nruab nrog cov cuab yeej hloov kho sib txawv, daim ntawv daim kab xev tuaj yeem hloov kho yooj yim yam tsis muaj lub tshuab nres;

Built-in valve chaw nres nkoj lossis chaw nres nkoj sab nraud tuaj yeem tsim tau; Barrel-shaped valve chaw nres nkoj thiab tus ntiv tes xoo-kawg valve chaw nres nkoj tuaj yeem tsim tau.

Hloov cov kev ntsuas ntawm qhov screen los teeb lub valve chaw nres nkoj ntawv ntev.

● Internal reinforcement mechanism *

Kev kho cov txheej txheem coj cov ntawv txuas ntxiv mus rau txoj hauv kev.Tom qab ntawd daim ntawv hla lub traction thiab txiav mechanism rau folding yob thiab pinch yob. Daim ntawv pinched los ntawm pinch yob taug kev los ntawm cov nplaum nplaum thiab ces muab tso rau ntawm lub hnab.

Hluav taws xob tswj qhov system soj ntsuam cov txheej txheem. Yog tias tsis muaj lub hnab nyob rau hauv txoj hauj lwm, kev tswj xyuas yuav tshem tawm cov ntawv pinching kom cov ntawv yuav tsis tau glued thiab yuav raug xa mus rau qhov tawm.Thiab cov nplaum nplaum yuav cais tawm ntawm cov pinch yob.

Nruab nrog cov cuab yeej hloov kho qhov sib txawv, tuaj yeem hloov kho txoj haujlwm ntawm daim ntawv daim kab xev tsis tas yuav tsum siv lub tshuab.

Hloov cov kev ntsuas ntawm qhov screen los teeb lub valve chaw nres nkoj ntawv ntev.

● Hauv qab kaw thiab gluing mechanism

Nruab nrog lub hnab ntawv hauv qab indentation ntaus ntawv los pab hauv qab txoj kev.

Nruab nrog lub tshuab ua kua nplaum loj loj.Raws li qhov sib txawv ntawm lub hnab ntawv loj specifications thiab cov txheej txheem yuav tsum tau, flexibly hloov cov duab ntawm cov roj hmab phaj.

Nruab nrog kev sib cais system.Thaum kuaj pom tias tsis muaj lub raj xa dej ntawm qhov chaw xa khoom lossis hauv qab ntawm lub raj xa ntawv tsis qhib, qhov kev sib cais yuav cia li tawm ntawm lub log loj loj, yog li lub raj xa ntawv yuav tsis raug glued.

● Lub hnab tsim mechanism

Cov cuab yeej tsim yog tsim los ntawm sab sauv thiab sab hauv core daim hlau thiab sab saud thiab qis.

cov txheej txheem txheej txheej.Lub hnab lub tis yog kev txhawb nqa los ntawm lub hauv paus core board, thiab cov txheej txheem txheej txheej yog coj mus rau quav thiab tsim ib lub square hauv qab, ua rau cov muab tshuaj txhuam kom ruaj los ntawm lub log compaction.

Qhov loj ntawm cov tub ntxhais sab sauv thiab sab hauv qab tuaj yeem hloov kho raws li qhov xav tau ntawm cov ntawv sib txawv hauv qab qhov ntau thiab tsawg.

● Hauv qab kho cov txheej txheem

Hauv qab ntawm lub hnab yog ntsug tom qab tsuas yog pasted.Rau zoo dua compaction thiab overlapping conveying, hauv qab ntawm lub hnab yuav tsum tau fipped ntawm 90-degree lub kaum sab xis kom haum lub hnab lub cev. Flipping & taw qhia bar nce thiab nqis kom maj mam flatten hauv qab ntawm lub hnab mus rau hauv lub compaction conveyor siv.

● Compaction thiab suav mechanism *

Lub hnab ntawv nkag mus rau hauv txoj siv qeeb qeeb, thiab cov nyhuv compaction yog pom tseeb dua tom qab stacking.

Nruab nrog suav cov cuab yeej, preinstall tus naj npawb ntawm suav cov hnab ntawv tuaj yeem teeb tsa.

Nruab nrog lub tshuab nqus tsev adsorption thiab nrawm sib cais cov cuab yeej, uas yog siv los cais cov ntawv ntim cov hnab ntawv tom qab ncav cuag tus naj npawb ntawm cov hnab ntawv teev los ntawm lub kaw lus.

● Outputing mechanism

Thaum nkag mus rau lub hnab tawm mechanism, lub hnab ntim rau hauv qhov chaw stacking. Tom qab tus naj npawb ntawm cov hnab ntawv mus txog tus nqi preinstalling, lub stacking cheeb tsam valve qhib, thiab hauv qab conveyor txoj siv yuav pib. Tom qab ntawd cov hnab ntawv ntim khoom thauj mus rau lub hnab ntim khoom, thiab cov hnab ntawv yog palletized los ntawm cov neeg ua haujlwm.