Carton Board Flute Laminator Machine

Machine Photo

Apply Photo

● The feeding unit is equipped with a pre-piling device to increase the production efficiency.

● High strength feeder uses 4 lifting suckers and 4 forwarding suckers to ensure smooth running with no missing of sheet even at high speed.

● The electric control system with touch screen and PLC program monitors automatically the working condition and facilitate trouble shooting. The electric design conforms to the CE standard.

● Gluing unit uses high precise coating roller, together with specially designed metering roller enhances the evenness of gluing. The unique gluing roller with glue stopping device and automatic glue level control system guarantees backflow with no overflow of glue.

● Machine body are processed by CNC lathe in one process, which ensures the precise of every positions. Toothed belts for transferring guarantees smooth running with low noise. Motors and the spares uses Chinese famous brand with high efficiency, less trouble and long service life.

● Corrugated board feeding unit adopts powerful servo motor control system with the features of high sensitivity and fast speed. The suction unit uses unique dust collection filter box,which enhances suction force for different corrugated paper, ensuring smooth running with no double or more sheets, no missing of sheets.

● The pressure of the rollers are adjusted synchronously by one hand wheel, easy to operate with even pressure, which ensures the flute not to be damaged.

● All material bought from outside are inspected and the key parts such as bearings are imported ones.

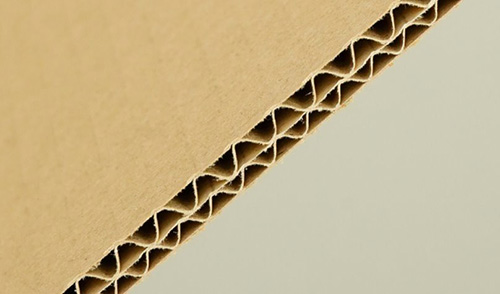

● The bottom sheet for this machine can be A, B, C, E, F flute corrugated sheet. The top sheet can be 150-450 GSM. It can do 3 or 5 ply corrugated board to sheet lamination with the thickness not more than 8mm. It has top paper advance or alignment function.

| Model | LQM1300 | LQM1450 | LQM1650 |

| Max. Paper Size (W×L) | 1300×1300mm | 1450×1450mm | 1650×1600mm |

| Min. Paper Size (W×L) | 350x350mm | 350x350mm | 400×400mm |

| Max. Mechanical Speed | 153m/min | 153m/min | 153m/min |

| Bottom Sheet | A,B,C,D,E Flute | ||

| Top Sheet | 150-450gsm | ||

| Total Power | 3 Phase 380v 50hz 16.25kw | ||

| Dimensions (LxWxH) | 14000×2530×2700mm | 14300x2680×2700mm | 16100x2880×2700mm |

| Machine weight | 6700kg | 7200kg | 8000kg |

● Our Flute Laminator products are known for their exceptional performance, durability, and value, meeting the needs of our customers worldwide.

● The company takes "unity, pragmatism, integrity and innovation" as the core concept of the enterprise, always pursues internationalization, standardized management, honesty, and returns to the society with accurate research and development technology, high-end product quality, and professional after-sales service.

● We take pride in our reputation for quality and reliability, and we strive to exceed our customers' expectations every time.

● As a way to provide you advantage and enlarge our organization, we even have inspectors in QC Crew and guarantee you our greatest assistance and product or service for Automatic Flute Laminator.

● At our factory, we take pride in our quality workmanship and attention to detail, ensuring that every Flute Laminator product we produce meets or exceeds our customers' expectations.

● The history of our company's development for many years is a history of honest management, which has won us the trust of our customers, the support of our employees and the progress of our company.

● Our success is driven by a commitment to quality, efficiency, and customer service, reflected in everything we do.

● With the increasingly fierce market competition, the improvement of sales and service channels has increasingly become a necessary factor for the development of our company.

● Our mission is to be the premier provider of high-quality Flute Laminator products and services worldwide.

● Welcome to monitor our company's compliance with the code of conduct and business practices.