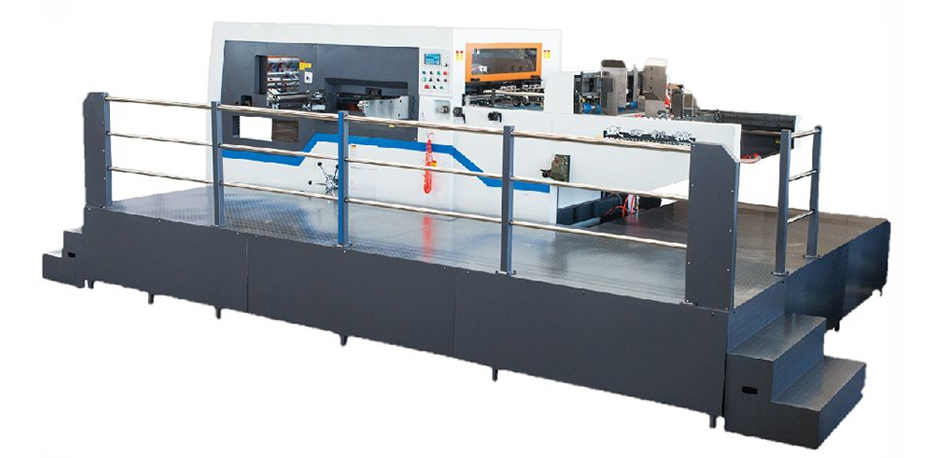

Automatic die cutting stripping machine

Machine Photo

This machine is a special equipment for die-cutting of high-end color corrugated boxes, which is innovatively developed by our company, and realizes automation from paper feeding, die-cutting and paper delivery.

● The unique lower sucker structure can realize continuous non-stop paper feeding and effectively avoid the scratch problem of the color boxes.

It adopts advanced mechanisms such as high-precision intermittent indexing mechanism, Italian pneumatic clutch, manual pressure regulation, and pneumatic chase locking device.

● The rigorous and precise manufacturing process guarantees accurate, efficient and stable operation of the whole machine.

● The paper feeding adopts mechanical transmission to ensure stable working; the non-stop paper feeding increases the working efficiency; the unique anti-scratch mechanism enables the paper surface is not scratched; the paper feeding is controlled by a servo motor which ensures smooth feeding and accurate positioning.

● The machine body, bottom platform, moving platform and the upper platform are made of high-strength nodular cast iron to ensure the machine no deformation even working at a high speed. They are processed by a large five-sided CNC at one time to ensure the accuracy and durability.

● This machine adopts precise worm gear and crankshaft connecting rod mechanism to ensure the stable transmission. All of them are made of high-grade alloy materials, processed by a large machining tools, which ensure the machine with stable operation, high die-cutting pressure, and high-point pressure holding.

● The high-resolution touch screen is used for human-computer interaction. The PLC program controls the operation of the whole machine and the trouble monitoring system. The photoelectric sensor the LCD screen are used throughout the work, which is convenient for the operator to monitor and eliminate hidden dangers in time.

● The gripper bar is made of special super-hard aluminum alloy materials, with anodized surface, strong rigidity, light weight, and small inertia. It can carry out precise die-cutting and precise control even the machine running at high speed. The chains are made in German to ensure accuracy.

● Adopt high-quality pneumatic clutch, long life, low noise and stable braking. The clutch is fast, with large transmission force, more stable and durable.

| Model | LQMX1300P | LQMX1450P |

| Max. Paper Size | 1320x960mm | 1450x1110mm |

| Min. Paper Size | 450x420mm | 550x450mm |

| Max. Die-Cutting Size | 1300x950mm | 1430x1100mm |

| Inner Size of Chase | 1320x946mm | 1512x1124mm |

| Paper Thickness | Corrugated board ≤8mm | Corrugated board ≤8mm |

| Gripper Margin | 9-17mm standard13mm | 9-17mm standard13mm |

| Max. Working Pressure | 300ton | 300ton |

| Max. Mechanical Speed | 6000sheets/h | 6000sheets/h |

| Total Power | 30kw | 30.5kw |

| Air Source Pressure/Air Flow | 0.55-0.7MPa/>0.6m³/min | |

| Net Weight | 23ton | 25ton |

| Overall Dimensions (LxWxH) | 9060x5470x2370mm | 9797x5460x2290mm |

● From small businesses to large industrial operations, our flatbed diecutting and stripping machines are trusted by customers worldwide.

● We have always insisted on taking innovation as the first driving force for development, and have never stopped R&D and innovation.

● We believe in going the extra mile to ensure our customers receive products that meet their exact specifications and are of the highest quality.

● We take the core values of "customer-oriented, technology-first; pragmatic and hard-working, honest and sensitive" as our foundation, and adhere to "fast response, continuous innovation, cost leadership, win-win cooperation.

● Our state-of-the-art equipment and experienced team of technicians allow us to deliver superior flatbed diecutting and stripping solutions to our customers.

● Our company mainly provides customers with durable and affordable Automatic Die Cutting Stripping Machine.

● Our flatbed diecutting and stripping machines are designed to streamline production processes, reducing costs and improving efficiency.

● The diversification of our company's market is to meet the changing needs of customers. Our company is a comprehensive enterprise. We operate independently from the development and production of products to the pre-sale and after-sale of products.

● Our team is committed to providing exceptional customer service, ensuring that our customers receive the support they need at every stage of the buying process.

● We have always been committed to scientific and technological management and continuous innovation to enable enterprises to embark on a virtuous circle of large-scale operations.