Automatic die cutting machine for corrugated boxes

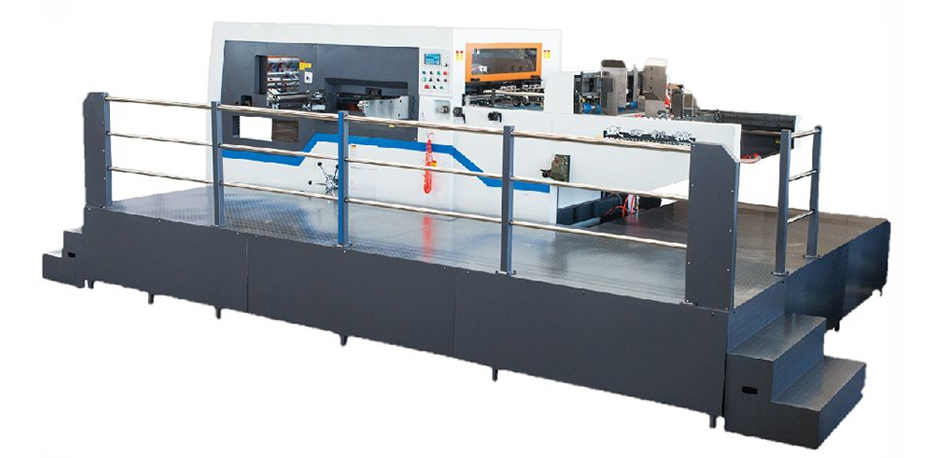

Machine Photo

This machine is a special equipment for die-cutting of high-end color corrugated boxes, which is innovatively developed by our company, and realizes automation from paper feeding, die-cutting and paper delivery.

● The unique lower sucker structure can realize continuous non-stop paper feeding and effectively avoid the scratch problem of the color boxes.

It adopts advanced mechanisms such as high-precision intermittent indexing mechanism, Italian pneumatic clutch, manual pressure regulation, and pneumatic chase locking device.

● The rigorous and precise manufacturing process guarantees accurate, efficient and stable operation of the whole machine.

● The paper feeding adopts mechanical transmission to ensure stable working; the non-stop paper feeding increases the working efficiency; the unique anti-scratch mechanism enables the paper surface is not scratched; the paper feeding is controlled by a servo motor which ensures smooth feeding and accurate positioning.

● The machine body, bottom platform, moving platform and the upper platform are made of high-strength nodular cast iron to ensure the machine no deformation even working at a high speed. They are processed by a large five-sided CNC at one time to ensure the accuracy and durability.

● This machine adopts precise worm gear and crankshaft connecting rod mechanism to ensure the stable transmission. All of them are made of high-grade alloy materials, processed by a large machining tools, which ensure the machine with stable operation, high die-cutting pressure, and high-point pressure holding.

● The high-resolution touch screen is used for human-computer interaction. The PLC program controls the operation of the whole machine and the trouble monitoring system. The photoelectric sensor the LCD screen are used throughout the work, which is convenient for the operator to monitor and eliminate hidden dangers in time.

● The gripper bar is made of special super-hard aluminum alloy materials, with anodized surface, strong rigidity, light weight, and small inertia. It can carry out precise die-cutting and precise control even the machine running at high speed. The chains are made in German to ensure accuracy.

● Adopt high-quality pneumatic clutch, long life, low noise and stable braking. The clutch is fast, with large transmission force, more stable and durable.

● Adopts the delivery table for paper collecting, the paper pile is automatically lowered, and when the paper is full it will automatically alarms and speeds down. The automatic paper arranging device runs smoothly with simple adjustment and neat paper delivery. Equipped with an anti-return photoelectric detection switch to prevent the paper stacking table from being over height and paper rolling.

| Model | LQMX1300P | LQMX1450P |

| Max. Paper Size | 1320x960mm | 1450x1110mm |

| Min. Paper Size | 450x420mm | 550x450mm |

| Max. Die-Cutting Size | 1300x950mm | 1430x1100mm |

| Inner Size of Chase | 1320x946mm | 1512x1124mm |

| Paper Thickness | Corrugated board ≤8mm | Corrugated board ≤8mm |

| Gripper Margin | 9-17mm, standard13mm | 9-17mm, standard13mm |

| Max. Working Pressure | 300ton | 300ton |

| Max. Mechanical Speed | 6000sheets/h | 6000sheets/h |

| Total Power | 30kw | 30.5kw |

| Air Source Pressure/Air Flow | 0.55-0.7MPa/>0.6m³/min | |

| Net Weight | 23ton | 25ton |

| Overall Dimensions (LxWxH) | 9060x5470x2370mm | 9797x5460x2290mm |

● Whether you need a simple flatbed diecutting machine or a more complex stripping solution, we have the expertise and resources to deliver the right product for your needs.

● Our company is accelerating the transformation and upgrading, focusing on building an industrial system with Automatic Diecutting Machine as the core and coordinated development of various industries, and comprehensively improving the core competitiveness and profitability of the industry.

● We offer a range of financing options to help our customers purchase the flatbed diecutting and stripping machines they need without breaking the bank.

● We attach great importance to the market dynamics, our Automatic Diecutting Machine are the current peer products of high quality products and the most competitive products.

● We understand that every customer's needs are different, which is why we offer customized solutions that meet their unique requirements.

● Our company expands its business by increasing the variety of products and services.

● We are always looking for ways to innovate and improve our products, helping our customers stay ahead of the competition in their industries.

● Through years of steady development, we are anxious about what customers want, think about what customers want, and respond to their needs.

● Our company offers a range of flatbed diecutting and stripping machines that deliver both precision and accuracy.

● We believe that only when the company has a good corporate image in the public, customers are willing to buy our Automatic Diecutting Machine or accept the services we provide.