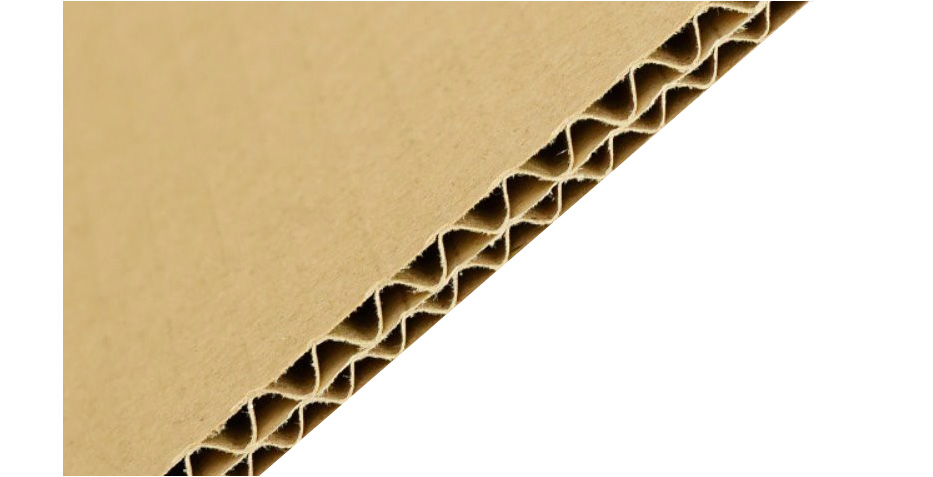

3 ply corrugated production line

Machine Photo

Apply Photo

1500H Hydraulic Mill Roll Stand

● Symmetry structure could install two bundles real paper at the same time, and change the paper without any stop.

● Adopt hydraulic drive that could make the real paper lift-lower, clamp and release and move.

● Adopt pneumatic strain to adjust the real paper.

● Expanding clips design.

● Tension control by multipoint brake system.

Rail and Pulley

● Push the real paper to the right position, handiness and agility.

● Track buried and main frame welded by 16 channel steel, sturdy and durable

● The steel plates above the scene welded after the installation.

● Match two dollies to install the paper from two sides.

900 Preheater

● The surface of the rolls are polished and plated with chrome.

● Electrical motion adjust of the dimension of per-heater, and the range of adjustment:60-270 degree

● Per-heater rolls professional manufactured, consistent with national safety standards for pressure vessels.

● Pre-heater roller and paper guide roll are plated.

● Electrical motion adjust of the dimension of per-heater, suit for different paper and speed.

320S 360S Single facer

● Paper guiding method adopts wind suction to keep the corrugated shape stable at high speed.

● The fan absorbs the corrugated paper in the 180 degree range of the middle corrugated roller through the vacuum box to form a negative pressure zone to complete the corrugated rolling.

● The width of the suction groove of the lower corrugated roller does not exceed 2.5mm, which can reduce the stripe marks of single-sided corrugated cardboard.

● The transmission part adopts universal joint transmission to isolate the vibration source, which makes the transmission more stable, reliable in operation and stronger in maintenance.

● The gearbox adopts oil-immersion lubrication and closed gear transmission to reduce machine vibration.

● Adopt automatic cycle of glue supply, pneumatic gluing and reset, with buffer effect.

● The gluing area is adjusted electrically, and the gluing part operates independently when the machine stops to prevent the paste from drying up.

● The surface of the sizing roller is treated with special mesh engraving and chrome plating.

● The gluing part is driven separately and can be pulled out for easy maintenance and cleaning.

● The corrugated rolling part is designed with a separate small wallboard, and the corrugated roller is convenient to disassemble, repair and replace the corrugated type.

● The upper and lower corrugated rollers are made of high-quality alloy steel and have been heat-treated with a hardness of HRC56-60 degrees. The surface is ground and chrome-plated.

Duplex Bridge

● The single-sided corrugated cardboard processed by the single facer is accurately sent to the tension brake or suction brake through the conveyor belt to the bridge conveyor for the next process.

● Using suction tensioning device, using 5.5KW high-pressure centrifugal frequency conversion fan to vacuum absorb and tension the cardboard, electric correction to ensure that the cardboard is firmly and flat.

● Electrical control is equipped with two operating panels, which can be adjusted in two places on the bridge.

● The delivery department adopts an independent frequency conversion control drive to synchronize with the single-facer. The single-faced corrugated board made by each single-facer is transported to the bridge to maintain a certain amount of single-faced corrugated board on the bridge. To compensate for the speed change of the production line, it is finally transported to multiple preheating and then preheated to the glue spreader and double-sided machine for bonding and forming.

● It is equipped with a paper conveying rack, and two sets of conveying belts are used for inclined setting. The speed of conveying and stacking is relatively slow, thus forming a wave-like overlap, which achieves the purpose of storing single-facer corrugated cardboard.

900T Double / Triple Preheater (Triple)

● Each roller surface is well whetted and chrome plated sooth and durable.

● Electrical motion adjust the dimension of pre-heater, the range of adjustment: 60-220 °.

● The pre-heating roller is made according to national container safety standard.

● Pre-heating roller and guiding paper roller are eclectically galvanized.

● Electrical motion adjust the dimension of pre-heater, suitable with different grades of paper and machinery speed.

318D Glue Machine

● Taiwan brand reducer motor, equipped with a frequency converter to control its running speed to synchronize with the hot plate, the main motor can run at a low speed in a short shutdown so that the paste will not dry up on the surface of the paste wheel.

● Paste thickness by electric digital display control, with the Chengbang of Taiwan gear reducer motor GH1/4HP*4P*1/4680. (plus decoderOEW2#×1).

● Pressure wheel or use electric adjustment, with the Chengbang of Taiwan gear reducer motor GH1/4HP*4P*1/4680.

318D Duplex Glue Machine

● Machine wall: made of 40MM thick steel plate, stable structure.

● The machine wall and the machine wall are connected with two 200# channel steel brackets and two 3 inch seamless pipe brackets.

Double Facer

● Overall high-strength wide channel steel structure, stable, beautiful and stable structure, suitable for high-speed work.

● The hot plate is professionally manufactured and meets the national pressure vessel safety standards. 600mm steel hot plate, multiple reinforcing ribs are welded to keep the hot plate not easy to deform.

● The heating section adopts a dense roller structure, and the cardboard is glued firmly and fixedly.

● The steam inlet and exhaust ports of the steam pipe are arranged in an S shape, and the temperature of the hot plate is balanced and uniform.

● The hot plate controls the temperature in sections to adapt to the adjustment of the vehicle speed.

● The upper cotton cloth belt is equipped with a set of automatic correction device, and the lower cotton cloth belt is equipped with a set of correction adjustment device.

Main Driver

● The driving part is a machine that connects the drying part and the cooling part provides movement energy for it.

● The main structure is steel plate and section steel, and two rubber wheels and paper guide wheels are added.

● The main body of the roller is made of high-grade wear-resistant rubber with a steel structure outer cylinder, which has good wear resistance and is not easy to slip.

● Independent gear box transmission.

● Drive roller diameter 745mm.

Computerized Slitter Scorer

● It can store 999 sets of orders, and realize automatic order change or manual order change without stopping.

● Quick order change, the order change time is 5-8 seconds, and the two machines can be used together to change the order immediately without slowing down.

● Automatically track the speed of the production line to ensure synchronization with it, and can be connected to the production management system with strong compatibility.

● With the cooperation of high-performance Taiwan Yonghong programmable controller and frequency conversion control, the order change speed is fast and the positioning is accurate.

● Three types of pressure line: convex to concave (three-layer line), convex to concave (five-layer line), convex to flat, three types of pressure line can be converted electrically. The depth of the crimping wheel can be automatically controlled by the computer, the line shape is good, and it is easy to bend.

Three types of pressure line: convex to concave (three-layer line), convex to concave (five-layer line), convex to flat, three types of pressure line can be electrically converted. The depth of the crimping wheel can be automatically controlled by the computer, the line shape is good, and it is easy to bend.

● Using thin tungsten steel alloy blade, the blade is sharp and the service life is more than 8 million meters.

● Blade sharpening automatic sharpening or manual sharpening, which can sharpen the blade while cutting and improve production efficiency.

● Adopt imported synchronous drive device, accurate precision, long life and low running noise.

● The blade sharpening is controlled by PLC automatically or manually, which can be sharpened while cutting to improve production efficiency.

● Imported synchronous drive device is adopted, with accurate precision, long service life and low running noise.

150N 200N NC Cut Off

● Design of special structure, mechanical wall board and base with excellent strength. The two sides of the wallboard are equipped with perspective window, which is convenient for observation and maintenance.

● The transmission system is automatically lubricated by the oil pump to ensure the transmission accuracy.

● High precision, high hardness grinding gear, high speed resistance, long life, ensure accurate blade engagement, flat paperboard without burrs.

● High precision tool spindle, tool holder design, high speed cutting, very smooth.

● The structure design of special exchange knife is very quick and convenient.

● The whole system is designed and manufactured by C.E standard, and has passed strict industrial grade computer test to ensure the quality, life and stability.

● The driving part adopts AC servo drive, fast response and accurate action.

● Using special power recovery storage design, the power saving effect is excellent, and it has the advantages of overcoming the unstable power plant environment.

● The system has automatic detection function, which can prevent the loss of equipment caused by abnormal operation and careless operation.

● The computer can automatically adjust the paper cutting speed according to the board specification and production speed; it can automatically track the running speed of the paperboard and keep the synchronization.

● Computers can store up to 999 sets of orders and automatically complete them in sequence or according to priority conditions.

● Paper length 500~9999mm, paper cutting accuracy + 1mm.

● Spiral knife used in Taiwan.

● The cutter shaft bearing is made in Japan NSK, which is convenient for high speed operation and durability of the equipment.

200P Small Gantry Stacking Machine

● Frequency conversion motor and frequency converter control cardboard superimposed conveying, and the conveying speed is synchronized with the cardboard speed;

● Automatic counting, automatic stack change and order change, accurate stack change and order change without damage to the cardboard;

● Gantry stacking, controlled lifting, stacking is stable, tidy, and does not damage the cardboard;

● Flat belt stacking platform, when stacking reaches the set number, frequency conversion control will automatically and smoothly output paper horizontally;

● The rear baffle automatically controls the positioning, and adjusts automatically, quickly and accurately when changing orders;

● The paper output side is equipped with two rows of metal roller paper receiving racks, the paper does not damage the cardboard, and it is convenient to directly flip, pack and stack;

● Standard 7" color touch screen, convenient for on-site operation and monitoring;

● The standard communication interface can be connected to the central monitoring and management system to realize automatic order change and order management;

● Fully automatic operation control, improve efficiency, save manpower, and reduce labor intensity of operators.

| Max. Mechanical Speed | LQWJ150-1800 3 Layer Corrugated Carton Production Line (150m/min) |

| LQWJ200 (200m/min) | |

| Production Line Length | LQWJ200 (About 59 meters;) |

| LQWJ150-1800 (About 60 meters) | |

| Flute Profiles | A, C, B, E flute |

| Total Power | 3 Phase 380v 50hz 260kw |

| Design Speed | 150m/min |

| Economy Speed | 120-130m/min |

| Production Line Length | About 73m |

| Total Power | 3 Phase 380v 50hz 275kw |

● We are committed to quality, reliability, and customer satisfaction in the production of Multi Layer Corrugated Board Production Line products.

● Our company business tenet of quality first, reputation first, and serve users wholeheartedly for the projects undertaken by our company. With our advanced technology and high-quality service, we will serve for client's benefits. And our company is willing to work together with you to create a promising future.

● We have an extensive network of distributors and partners to ensure that our Multi Layer Corrugated Board Production Line products are available worldwide.

● Thanks to technological and technological breakthroughs, our company has embarked on a fast-growing express track, with continuous expansion of production capacity.

● Our customer-focused approach makes us stand out as a leading provider of Multi Layer Corrugated Board Production Line products and services.

● Our company adheres to the business philosophy of 'Quality, Safety, and Efficiency', and is committed to providing customers with high-quality products, excellent solutions and perfect and professional after-sales service. We will develop together with our customers with a sincere attitude.

● Our aim is to provide our customers with the best Multi Layer Corrugated Board Production Line products and services that are tailored to their unique needs.

● Our company's image, credibility, product technical quality assurance and production capacity have received high praise and unanimous praise from experts and users.

● As a leading manufacturer and supplier, we are proud to offer high-quality Multi Layer Corrugated Board Production Line products and expert services.

● Under the principle of total quality management, our pursuit of 3 Ply Corrugated Production Line quality is continuous.

● Our multi-layer corrugated board production line products are guaranteed to meet international standards and regulations.

● While striving to create a better society, our strong sense of responsibility allows us to lead our 3 ply corrugated cardboard production line towards environmental protection and energy saving.

● We offer a range of after-sales services to ensure that our customers are satisfied with our Multi Layer Corrugated Board Production Line products.

● Our company has always been in line with the corporate tenet of 'thinking from the perspective of customers', using practical actions to provide new and old customers with comprehensive services and high-quality 3 ply corrugated cardboard production line.

● Our multi layer corrugated board production line products are suitable for a variety of applications and industries.

● Give full play to the development advantages of integrating design and research, manufacturing and installation, operation management, and innovation and promotion, seize development opportunities, focus on innovation, continuously adjust product structure, and focus on the construction of characteristic 3 ply corrugated cardboard production line industry.

● Our team of experts can provide technical advice and support to help you choose the right multi layer corrugated board production line products for your needs.

● Adhering to the concept of innovation and development, integrity wins the world, the company continues to increase investment in scientific and technological research and development.

● Our in-house development team is always working on new and innovative multi layer corrugated board production line products and services.

● To establish a good corporate culture, to strengthen the internal standardized management, to achieve people-oriented management, and to effectively motivate employees are the contents that our company needs to gradually establish and improve in the continuous development.

● Our Multi Layer Corrugated Board Production Line products are highly durable and long-lasting to ensure maximum value for our customers.

● We establish modern cost management consciousness and penetrate cost consciousness into the whole process of decision making, investment, production and sales through management innovation, especially by strengthening strategic cost management.

● We offer competitive pricing without compromising on the quality of our Multi Layer Corrugated Board Production Line products.

● Our company is a newly emerging private enterprise in the industry of 5 Ply Corrugated Cardboard Production Line, with large-scale factories and professional technicians. Our equipment is advanced and the product range is complete, and our annual production capacity can meet the needs of a large number of customers. In addition, we have an independent design, research and development, and manufacturing capabilities, so we are very competitive.

● Our Multi Layer Corrugated Board Production Line products are designed to optimize performance and productivity in various applications.

● Responsibility, innovation, integrity, and win-win are our corporate culture.

● Our experienced team of professionals is dedicated to providing customers with the best Multi Layer Corrugated Board Production Line products and services.

● We use excellent values to motivate employees to devote themselves to the spirit of the enterprise.

● Our skilled workforce is dedicated to producing Multi Layer Corrugated Board Production Line products that meet the highest standards.

● The innovation mechanism provides a fundamental guarantee for the optimal allocation of enterprise resources and the enhancement of competitiveness.